Artificial intelligence (AI) has become the centerpiece of nearly every business conversation today. From optimizing supply chains to enhancing customer engagement, AI is being hailed as the next great enabler of operational efficiency.

Yet, behind the buzz, many mid-market manufacturers and distributors remain uncertain about what it truly means for their business models and systems.

Recent industry analyses highlight a growing disconnect between aspiration and readiness. While organizations are racing to integrate AI into their processes, few possess the data maturity or system alignment to translate experimentation into measurable outcomes.

Successful implementations, as seen in leading manufacturers and distributors, do not rely on adopting standalone AI tools. Instead, they focus on building intelligence into the existing infrastructure, whether it is ERP and supply chain systems or eCommerce and order management platforms, so that insights and automation emerge naturally from day-to-day operations.

This distinction marks a shift from technology adoption to business transformation.

For most B2B firms, the immediate opportunity lies not in reinventing their systems but in enhancing them.

When applied thoughtfully, AI strengthens the core engines of commerce: forecasting, inventory management, product information accuracy, and service responsiveness.

This is where AI in B2B moves from hype to hands-on practice. The following sections examine how mid-market businesses are beginning to use AI in practical, incremental ways, integrating intelligence where it drives measurable value and building momentum toward a more connected, adaptive enterprise.

Artificial intelligence in B2B is often portrayed as a singular breakthrough, a technology that can automate entire processes or make human expertise redundant. In practice, AI functions less as a replacement and more as an amplifier. It builds on existing digital foundations such as ERP, CRM, and eCommerce platforms to create systems that learn, predict, and adapt over time.

At its core, AI in B2B eCommerce combines three essential capabilities.

This layered approach makes AI less of a discrete product and more of a cognitive layer across the business.

For B2B manufacturers, it might mean anticipating raw-material requirements based on seasonality or order history.

For B2B distributors, it could involve improving fill-rate accuracy by predicting order patterns across multiple warehouses. In both cases, the value lies in embedding intelligence within systems already central to operations.

As a recent survey by ABI Research on AI in supply chain suggests , firms that succeed with AI are those that treat it as an enabler of data fluency, not an external solution.

Rather than deploying tools in isolation, they integrate them into the connective tissue of the enterprise—ERP, order management, product catalogs, and logistics—creating visibility, speed, and precision at scale.

Artificial intelligence is not a single technology. In practice, it appears in distinct layers that range from simple process automation to systems capable of reasoning and acting independently.

Understanding these layers helps business leaders identify where the immediate value lies and where preparation must begin for what comes next.

Across the mid-market, automation looks very different from one organization to another.

Some manufacturers and distributors have integrated workflows through ERP, CRM, or warehouse management systems. Others still depend on spreadsheets, emails, or manual approvals to keep operations moving.

Whatever the stage, automation remains the operational baseline; the discipline that turns everyday processes into structured, repeatable actions.

Common examples include:

These rule-based processes form the connective tissue of business operations, ensuring speed and accuracy at scale.

Example:

A lighting distributor monitors stock across regional warehouses. When inventory for a fast-moving SKU falls below a predefined level, the ERP automatically creates a purchase requisition, updates the replenishment queue, and alerts procurement, without manual intervention.

These systems execute flawlessly within known parameters but stop short of adaptation.

When disruptions occur—supplier delays, freight constraints, or unexpected demand—they cannot assess context or recalibrate priorities on their own.

That is where intelligence begins: the ability not just to act, but to decide

For companies that still rely heavily on manual processes, the next step is clear: Establishing consistent digital workflows. It could be through an ERP rollout, process mapping, or structured data capture.

This creates the rhythm and visibility that intelligent technologies later build upon.

Strengthening automation is not a marker of lag; it is the clearest sign of readiness. Each well-defined workflow increases transparency, reduces variability, and brings the organization closer to a data environment where predictive and generative AI can deliver measurable value.

Progressing from automation, predictive AI shifts operations from “what happened” to “what’s likely to happen next.” In fact, major B2B distributors such as Grainger and Fastenal have been treating AI and digital capability as core infrastructure , and not just optional add-ons.

However, the shift must be less about installing a flashy tool and more about turning existing data into foresight.

Predictive AI is the first layer that delivers measurable business impact when systems, data and processes are aligned.

In catalog-heavy industries such as apparel, predictive models might analyze past sell-through, regional weather patterns and evolving style trends to forecast demand ahead of production runs, reducing markdown risk and improving margin.

For industrial or lighting distributors, predictive analytics can forecast which parts or supplies are likely to be in heavy demand next quarter, enabling smarter inventory placement or strategic sourcing before the bottlenecks strike.

Predictive intelligence doesn’t replace systems like ERP, order-management or eCommerce, but it augments them. The sequence often looks like this:

When data is fragmented or inconsistent, the predictive layer weakens. That’s why readiness matters and why investment in connected workflows, as mentioned in previous point, pays off here.

Organizations trying to navigate the complex world of AI should start by identifying one domain where data is rich and volume is high.

This could be often inventory, demand forecasting or reorder cycles. A successful pilot here builds confidence and creates momentum for broader application.

As the ABI survey indicates, the readiness gap isn’t about technology alone, but about preparing data, process, and teams.

By treating predictive AI as the next evolutionary step, businesses can convert ambition into measurable outcomes rather than chasing accidental experiments.

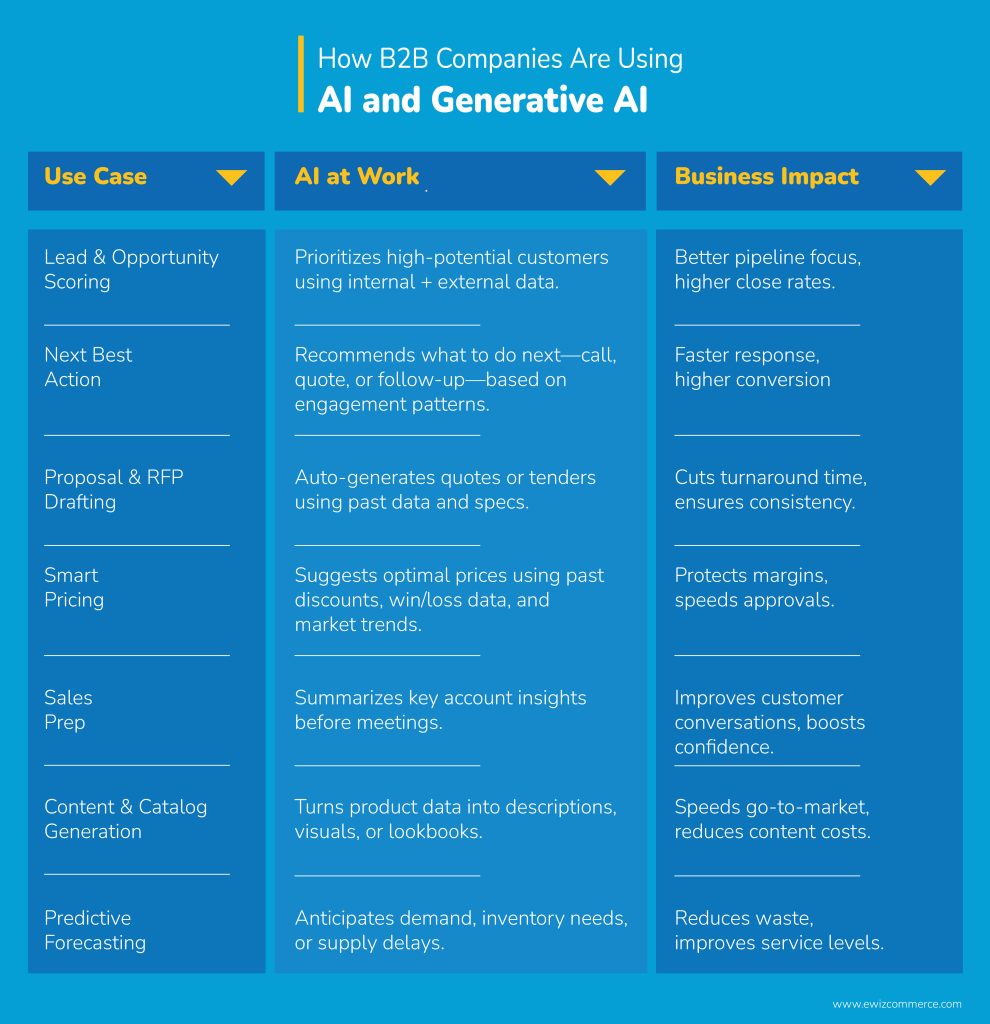

The leap from predictive insight to full-scale agility comes with generative AI and, even more so, Agentic AI or Agentic Commerce. These represent the stage where systems don’t just tell you what will happen—they help create what you need or act on your behalf.

What generative AI brings

Generative AI uses large language models, image synthesis, and data-driven creation tools to generate new content, designs, or workflows.

In B2B commerce, these capabilities can rapidly turn structured product data into rich descriptions, lifestyle imagery, configuration guides, or personalized digital catalogs.

This means an apparel and fashion B2B company can create seasonal lookbooks and product tags, which involves turning technical specs into customer-facing content, within 48 hours instead of weeks.

What agentic AI offers

Agentic AI takes things further. It’s about systems that reason and act. It monitors your systems, simulates scenarios, makes decisions, and executes across platforms (ERP, eCommerce, logistics) with minimal human intervention.

B2B revenue leaders are now designing architectures around agentic AI capabilities, moving from efficiency gains to transformation of how business gets done.

For example, if a distributor’s system detects that a primary supplier will miss delivery, it will trigger alternate sourcing, update customer portal ETAs, and reroute fulfillment, all without a manual “alert.”

As these capabilities mature, they converge into what the industry increasingly calls agentic commerce, a model where intelligent systems autonomously manage parts of the buying and selling cycle.

In this architecture, AI agents not only forecast or create but also execute: rerouting orders, adjusting prices, or triggering supplier communications without waiting for human input.

While still emerging, agentic commerce signals the next frontier of digital transformation.

For businesses building strong predictive and generative foundations today, it represents the logical destination: a future where commerce becomes self-steering, adaptive, and inherently intelligent.

There is a significant cost implication to investing in generative and agentic systems, which require clean, integrated data; cross-system connectivity; clear governance; and a culture willing to trust AI-driven decisions.

So how to begin investing?

If it’s not yet time: Focus on deeper predictive-AI maturity and stronger integrations. Without them, generative or agentic projects risk becoming costly experiments.

For all its promise, AI still intimidates many B2B manufacturers and distributors. Not because the potential is unclear, but because the path forward rarely is.

Most organizations are juggling legacy systems, fragmented data, and manual workarounds that were never designed to support machine learning or automation.

Recent industry research reinforces this tension. ABI Research reports that while over 80 percent of manufacturers and distributors plan to embed AI in their supply-chain operations, few have the data maturity or cross-system visibility to make those ambitions real. The readiness gap isn’t about enthusiasm, but about execution.

Even digitally active companies discover that once they start experimenting, AI adoption introduces new challenges:

The irony is that every barrier points to the same underlying issue: disconnection. Systems don’t talk, data doesn’t flow, and insight rarely turns into action. Until those gaps close, even the best algorithms struggle to add measurable value.

So What Next?

Artificial intelligence will not transform a business overnight. But structured progress will. The companies that win with AI are rarely the ones chasing novelty; they are the ones that modernize methodically.

Start by ensuring every core process—orders, inventory, pricing, product data—runs cleanly and consistently.

Strengthen automation, connect your systems, and let predictive models learn from the data you already own.

From there, generative and agentic capabilities can follow naturally, embedded where they make the most sense.

The real opportunity isn’t in adding another AI tool; it’s in building an intelligent architecture that learns continuously and acts decisively. That’s how B2B businesses evolve from automation to autonomy, and how the hype around AI becomes something measurable, sustainable, and real.

At ewiz commerce, we help B2B businesses move from automation to autonomy, building intelligent, integrated systems that make AI practical, measurable, and scalable. If you’re ready to turn AI potential into performance, let’s start the conversation.